Before we get to the interview I wanted to mention today’s sponsors,

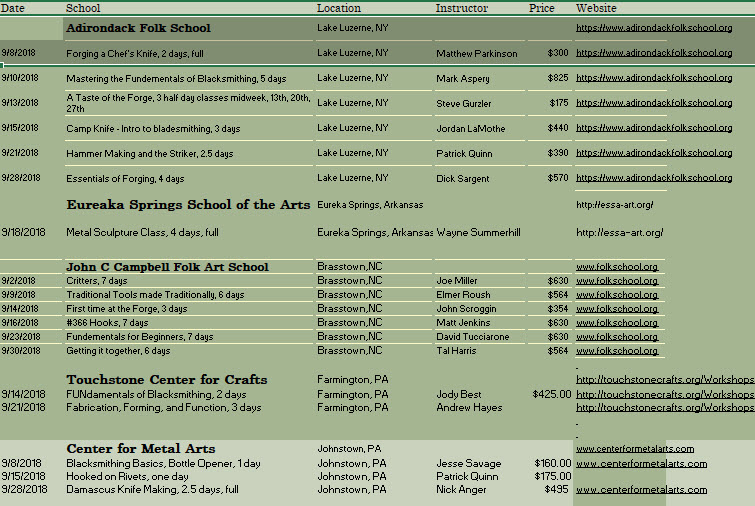

First we have the Adirondack Folk School. It’s a non-profit school located in Lake Luzerne, in upstate New York. The blacksmithing program at the Folk School includes 24 classes with an incredible line of blacksmithing instructors this year. To see the complete list of classes or to register, visit their website: www.adirondackfolkschool.org.

I’d also like to thank the New England Blacksmiths, the ABANA affiliate serving Connecticut, Massachusetts, Vermont, New Hampshire, Maine and Rhode Island. Who by the way will be driving the ABANA 2020 Conference in Saratoga, NY

Check us out at http://www.newenglandblacksmiths.org/

Also They will be offering the Age of Iron weekend event at the Hancock Shaker Village in Pittsfield, Massachusetts, It’s happening the 1st weekend in August, 3rd and 4th.

Those interested in further details can contact Cindy Dickinson at [email protected]

or DM @HayBudden on Twitter or Instagram. If you mention I’m here for the blacksmithing you’ll get an extra $5 off at the door!

Thanks NEB!

OK, let’s dive right into this interview with Pete.

What We Talked About

- Pete first went to a technical college for welding, then he got a job as an apprentice was with an industrial blacksmith at the Ipswitch railyards in Queensland, Australia. There he forged a lot of industrial tools for mines, alloy steel forging.

- Pete decided to go to art school and received his Bachelor of Fine art. He then received a scholarship for his master’s in fine art.

- Pete talks about his apprentice journey through the United States, which included working with Albert Paley, Mountain Forge and included a research residency at the Metal Museum.

- We talk about his design process which he includes 3 basic things: additive process, subtractive process and material displacement.

- When Pete works with clients for commissioned pieces, one of the things he asks for is 3 words from the client that encapsulates what they envision.

- About 80% of the time Pete sandblasts his sculptures first and then adds a chemical called Black Fast. Also follows up with beeswax.

- One of Pete’s goals this year is to convert his gas forge into a veggie oil burning forge.

Guest Links

- Website - https://www.petemattila.com/

- Instagram is @pete_mattila_

Before we get to the interview I wanted to mention today’s sponsors,

First we have the Adirondack Folk School. It’s a non-profit school located in Lake Luzerne, in upstate New York. The blacksmithing program at the Folk School includes 24 classes with an incredible line of blacksmithing instructors this year. To see the complete list of classes or to register, visit their website: www.adirondackfolkschool.org.

I’d also like to thank the New England Blacksmiths, the ABANA affiliate serving Connecticut, Massachusetts, Vermont, New Hampshire, Maine and Rhode Island. Who by the way will be driving the ABANA 2020 Conference in Saratoga, NY Check us out at http://www.newenglandblacksmiths.org/ Also They will be offering the Age of Iron weekend event at the Hancock Shaker Village in Pittsfield, Massachusetts, It’s happening the 1st weekend in August, 3rd and 4th.

Those interested in further details can contact Cindy Dickinson at [email protected] or DM @HayBudden on Twitter or Instagram. If you mention I’m here for the blacksmithing you’ll get an extra $5 off at the door!

Thanks NEB!

OK, let’s dive right into this interview with Pete.

What We Talked About

- Pete first went to a technical college for welding, then he got a job as an apprentice was with an industrial blacksmith at the Ipswitch railyards in Queensland, Australia. There he forged a lot of industrial tools for mines, alloy steel forging.

- Pete decided to go to art school and received his Bachelor of Fine art. He then received a scholarship for his master’s in fine art.

- Pete talks about his apprentice journey through the United States, which included working with Albert Paley, Mountain Forge and included a research residency at the Metal Museum.

- We talk about his design process which he includes 3 basic things: additive process, subtractive process and material displacement.

- When Pete works with clients for commissioned pieces, one of the things he asks for is 3 words from the client that encapsulates what they envision.

- About 80% of the time Pete sandblasts his sculptures first and then adds a chemical called Black Fast. Also follows up with beeswax.

- One of Pete’s goals this year is to convert his gas forge into a veggie oil burning forge.

Guest Links

- Website - https://www.petemattila.com/

- Instagram is @pete_mattila_

I’d also like to thank today’s sponsor, Even Heat, they manufacture the finest heat treat ovens available, Even Heat Kiln was founded in 1948 and has steadily grown to become a major kiln manufacturer. Find your next heat treat oven at evenheat-kiln.com.

Maegan's website - www.ironmaeganmetalworks.com

I’d also like to thank today’s sponsor, Even Heat, they manufacture the finest heat treat ovens available, Even Heat Kiln was founded in 1948 and has steadily grown to become a major kiln manufacturer. Find your next heat treat oven at evenheat-kiln.com.

Maegan's website - www.ironmaeganmetalworks.com

]]>“Blacksmithing can be a portal to so many fascinating realms, far beyond the iron itself.” And that is the essence of how our interview went, I’m grateful to have Jeffery on the show to share his wisdom in so many realms and the same gratitude goes, of course, to those of you who continue to listen, thank you.

I’d also like to thank today’s sponsor, Even Heat, they manufacture the finest heat treat ovens available, Even Heat Kiln was founded in 1948 and has steadily grown to become a major kiln manufacturer. Find your next heat treat oven at evenheat-kiln.com.

Jeffery Funk's Website - http://jeffreyfunkmetalworker.com/

The New Agrarian School - http://www.newagrarianschool.org/

]]>“Blacksmithing can be a portal to so many fascinating realms, far beyond the iron itself.” And that is the essence of how our interview went, I’m grateful to have Jeffery on the show to share his wisdom in so many realms and the same gratitude goes, of course, to those of you who continue to listen, thank you.

I’d also like to thank today’s sponsor, Even Heat, they manufacture the finest heat treat ovens available, Even Heat Kiln was founded in 1948 and has steadily grown to become a major kiln manufacturer. Find your next heat treat oven at evenheat-kiln.com.

Jeffery Funk's Website - http://jeffreyfunkmetalworker.com/

The New Agrarian School - http://www.newagrarianschool.org/

]]>I've decided on a different format for this year's podcast. I sat down recently and came up with 3 main topics and questions within each topic. I will ask the next 10 or so guests the same questions and hopefully dive deep into their Design Process, Forging Process and Tool Making. Those are the 3 topics I’ll be asking my guests for the bulk of this year’s podcasts.

This podcast is sponsored by Evenheat, they manufacture the finest heat treat ovens available, Even Heat Kiln was founded in 1948 and has steadily grown to become a major kiln manufacturer. Find your next heat treat oven at evenheat-kiln.com.

]]>

I've decided on a different format for this year's podcast. I sat down recently and came up with 3 main topics and questions within each topic. I will ask the next 10 or so guests the same questions and hopefully dive deep into their Design Process, Forging Process and Tool Making. Those are the 3 topics I’ll be asking my guests for the bulk of this year’s podcasts.

This podcast is sponsored by Evenheat, they manufacture the finest heat treat ovens available, Even Heat Kiln was founded in 1948 and has steadily grown to become a major kiln manufacturer. Find your next heat treat oven at evenheat-kiln.com.

]]>

The exhibition submissions need to be sent to Hereford for 1st March:

Measured Making Exhibition

c/o Delyth Done

Hereford College of Arts

College Road

Hereford

HR1 1EB, United Kingdom

Please include your full address.

Hereford College of the Arts will be posting more details on their Instagram page @herefordanvils.

I wanted to let you know this podcast is sponsored by Evenheat, they manufacture the finest heat treat ovens available, Even Heat Kiln was founded in 1948 and has steadily grown to become a major kiln manufacturer. I know Patrick Quinn at the Center for Metal arts has one and is happy with it, so find your next heat treat oven at evenheat-kiln.com.

Guest Links

- Website - http://www.ambroseburne.co.uk/

- Hereford College of the Arts website

- Instagram for Hereford: @herefordanvils, @herefordarts

- Instagram is @ambroseburne

The exhibition submissions need to be sent to Hereford for 1st March:

Measured Making Exhibition

c/o Delyth Done

Hereford College of Arts

College Road

Hereford

HR1 1EB, United Kingdom

Please include your full address.

Hereford College of the Arts will be posting more details on their Instagram page @herefordanvils.

I wanted to let you know this podcast is sponsored by Evenheat, they manufacture the finest heat treat ovens available, Even Heat Kiln was founded in 1948 and has steadily grown to become a major kiln manufacturer. I know Patrick Quinn at the Center for Metal arts has one and is happy with it, so find your next heat treat oven at evenheat-kiln.com.

Guest Links

- Website - http://www.ambroseburne.co.uk/

- Hereford College of the Arts website

- Instagram for Hereford: @herefordanvils, @herefordarts

- Instagram is @ambroseburne

What We Talked About

- He attended a festival, the Festival of the Ax, as a demonstrator in Tomsk Russia, so he tells us about the festival and how he got invited. There were artists from over 100 different countries and 15 blacksmiths

- We really go deep into introducing the craft of blacksmithing to college students and how the use of past publications could be more available in college libraries.

- We touch on the “crowdfunding” idea for blacksmith conferences

- We talk about how hard it is to be an artist and to make a living at the same time.

Guest Links

- Website - https://www.annarkoplik.com/

- Instagram @michaeljbudd

What We Talked About

- He attended a festival, the Festival of the Ax, as a demonstrator in Tomsk Russia, so he tells us about the festival and how he got invited. There were artists from over 100 different countries and 15 blacksmiths

- We really go deep into introducing the craft of blacksmithing to college students and how the use of past publications could be more available in college libraries.

- We touch on the “crowdfunding” idea for blacksmith conferences

- We talk about how hard it is to be an artist and to make a living at the same time.

Guest Links

- Website - https://www.annarkoplik.com/

- Instagram @michaeljbudd

If you have an event or class you would like to submit, send an email to [email protected] and I will send you the details I need for the press release.

]]>

If you have an event or class you would like to submit, send an email to [email protected] and I will send you the details I need for the press release.

]]>

Before we get to the interview I wanted to mention today’s sponsor is again provided on behalf of the New England Blacksmiths, an ABANA affiliate serving Connecticut, Massachusetts, Vermont, New Hampshire, Maine, and Rhode Island. And also will be driving the ABANA 2020 Conference in Saratoga, NY

They’ve got a great website, check it out at http://www.newenglandblacksmiths.org/

What We Talked About

- Anna is currently finishing an artist residency at the Touchstone center for crafts, during this 4-week residency she has been working on making tools for herself.

- In exchange for Anna being able to use the school’s resources to make her tools during her residency, she helps out around the school, cleaning and assisting in other classes.

- The school’s blacksmith shop has 12 student coal forging stations, an instructor coal forge, each with an anvil and post vise, a room full of tongs and hammers, 2 power hammers and gas forges.

- In years past Anna has worked at the school as a studio technician and was able to assist some top-rated instructors that have taught there such as Tom Latane and Mark Aspery.

- She has a BFA from Pratt Institute, she focused on jewelry and also became interested in weaponry. This interest led her to take a bladesmithing class at the Peter’s Valley School of Craft, this opened up the world of blacksmithing to her.

- Anna ended up taking an assistant position in the blacksmith shop at Peters Valley for a summer and this helped her grow her skills at the forge.

- Another stepping stone for Anna was her winter apprenticeship with Atlas Forge where they focused on production blacksmithing.

Guest Links

- Website - https://www.annarkoplik.com/

- Instagram is @arkoplik

Before we get to the interview I wanted to mention today’s sponsor is again provided on behalf of the New England Blacksmiths, an ABANA affiliate serving Connecticut, Massachusetts, Vermont, New Hampshire, Maine, and Rhode Island. And also will be driving the ABANA 2020 Conference in Saratoga, NY They’ve got a great website, check it out at http://www.newenglandblacksmiths.org/

What We Talked About

- Anna is currently finishing an artist residency at the Touchstone center for crafts, during this 4-week residency she has been working on making tools for herself.

- In exchange for Anna being able to use the school’s resources to make her tools during her residency, she helps out around the school, cleaning and assisting in other classes.

- The school’s blacksmith shop has 12 student coal forging stations, an instructor coal forge, each with an anvil and post vise, a room full of tongs and hammers, 2 power hammers and gas forges.

- In years past Anna has worked at the school as a studio technician and was able to assist some top-rated instructors that have taught there such as Tom Latane and Mark Aspery.

- She has a BFA from Pratt Institute, she focused on jewelry and also became interested in weaponry. This interest led her to take a bladesmithing class at the Peter’s Valley School of Craft, this opened up the world of blacksmithing to her.

- Anna ended up taking an assistant position in the blacksmith shop at Peters Valley for a summer and this helped her grow her skills at the forge.

- Another stepping stone for Anna was her winter apprenticeship with Atlas Forge where they focused on production blacksmithing.

Guest Links

- Website - https://www.annarkoplik.com/

- Instagram is @arkoplik

If you have an event or class you would like to submit, send an email to [email protected] and I will send you the details I need for the press release.

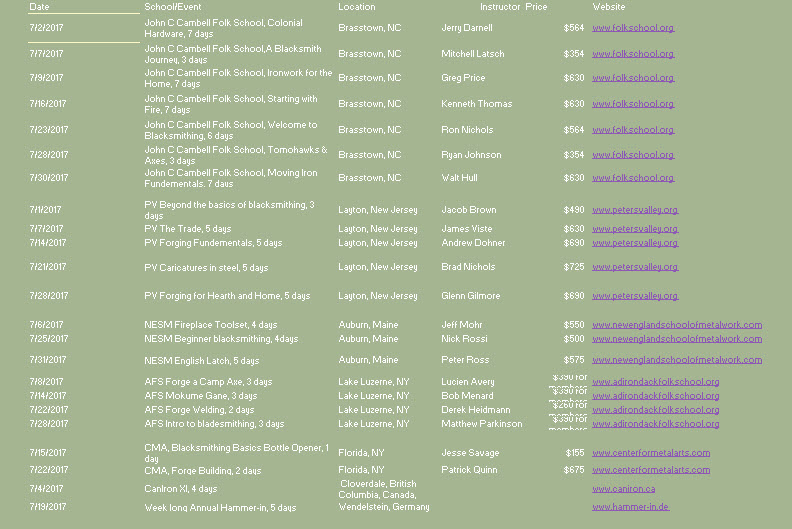

OK, I’ll go in Alphabetic order here:

If you have an event or class you would like to submit, send an email to [email protected] and I will send you the details I need for the press release.

OK, I’ll go in Alphabetic order here:

]]>

If you have an event or class you would like to submit, send an email to [email protected] and I will send you the details I need for the press release.

If you have an event or class you would like to submit, send an email to [email protected] and I will send you the details I need for the press release.

]]>

If you have an event or class you would like to submit, send an email to [email protected] and I will send you the details I need for the press release.

OK, I’ll go in Alphabetic order here:

If you have an event or class you would like to submit, send an email to [email protected] and I will send you the details I need for the press release.

OK, I’ll go in Alphabetic order here:

]]>What We Talked About

- Bob started working in an advertising agency after college and immediately knew that business suit and desk were not for him!

- He then accepted a production assistant job for a feature film, it was 1968, the spring Martin Luther King was murdered. NYC was becoming electrified, amped up, so Bob decided to move out of state and look for land in Wisconsin.

- After purchasing 4 acres and a house, his realtor took him by an old but still operating blacksmith shop that was for sale. He met the 80-year-old blacksmith, who was the second owner of the business, and decided to purchase the business from him for $500 (the building, the tools, the land)! The first owner opened the shop in 1856.

- Bob learned his basic blacksmith skills from a local country blacksmith, Thomas Kammerude, who lived up the road from Bob’s newly purchased shop.

- In 1976, Bob attended one of the first ABANA blacksmith conferences in Carbondale, Illinois. He met Francis Whitaker at this conference and he wanted to learn more from him, so Francis told him he had to take a class first at the John C Campbell folk school. Bob signed up long with Clay Spencer, Ray Nager, Glenn Gilmore, Jim Batson and more. They would all continue to take master classes from Francis for the next few years.

- Bob continued to travel through the US and apprentice with working blacksmiths during his slow winters. In 1985 he also traveled through Europe, doing a journeyman type program over 2 months, working in 12 to 15 different shops in different countries.

- In the late 1990’s he expanded the shop by adding 4000 sq ft building and a 3000 sq ft machine shop to complete bigger jobs.

- After 50 years in business, Bob is ready for retirement and looking for a buyer for the business, shop, tools and land. If you are interested in more details, you can contact Bob here, (608) 527-2494 or email [email protected].

- One “Golden Client” hired Bob to do a large amount of architectural work at his private home in Ridgeway CO, most of that work has been documented in the book called “Heritage in Iron”.

Guest Links

- Postville Blacksmith Shop: https://www.postvilleblacksmith.com/

- Old World Anvils: oldworldanvils.com

- The KA75 Striking Hammer: ka75.com

- Heritage in Iron book: https://bluemoonpress.org/index.php/heritage-in-iron.html

If you enjoyed this episode, I would love it if you would support the show by:

- telling your friends.

- sharing this episode using the social sharing buttons below.

- subscribing to the show and leaving a rating and review in iTunes. Not sure how? Just follow these simple steps here or watch the short video tutorial, http://youtu.be/rq4OCyRGjHc?list=UUH3MfNZLXlKgionAs6kMT_Q

- subscribing to the show in Stitcher, http://www.stitcher.com/s?fid=54499&refid=stpr

Thanks so much for your support!

]]>What We Talked About

- Bob started working in an advertising agency after college and immediately knew that business suit and desk were not for him!

- He then accepted a production assistant job for a feature film, it was 1968, the spring Martin Luther King was murdered. NYC was becoming electrified, amped up, so Bob decided to move out of state and look for land in Wisconsin.

- After purchasing 4 acres and a house, his realtor took him by an old but still operating blacksmith shop that was for sale. He met the 80-year-old blacksmith, who was the second owner of the business, and decided to purchase the business from him for $500 (the building, the tools, the land)! The first owner opened the shop in 1856.

- Bob learned his basic blacksmith skills from a local country blacksmith, Thomas Kammerude, who lived up the road from Bob’s newly purchased shop.

- In 1976, Bob attended one of the first ABANA blacksmith conferences in Carbondale, Illinois. He met Francis Whitaker at this conference and he wanted to learn more from him, so Francis told him he had to take a class first at the John C Campbell folk school. Bob signed up long with Clay Spencer, Ray Nager, Glenn Gilmore, Jim Batson and more. They would all continue to take master classes from Francis for the next few years.

- Bob continued to travel through the US and apprentice with working blacksmiths during his slow winters. In 1985 he also traveled through Europe, doing a journeyman type program over 2 months, working in 12 to 15 different shops in different countries.

- In the late 1990’s he expanded the shop by adding 4000 sq ft building and a 3000 sq ft machine shop to complete bigger jobs.

- After 50 years in business, Bob is ready for retirement and looking for a buyer for the business, shop, tools and land. If you are interested in more details, you can contact Bob here, (608) 527-2494 or email [email protected].

- One “Golden Client” hired Bob to do a large amount of architectural work at his private home in Ridgeway CO, most of that work has been documented in the book called “Heritage in Iron”.

Guest Links

- Postville Blacksmith Shop: https://www.postvilleblacksmith.com/

- Old World Anvils: oldworldanvils.com

- The KA75 Striking Hammer: ka75.com

- Heritage in Iron book: https://bluemoonpress.org/index.php/heritage-in-iron.html

If you enjoyed this episode, I would love it if you would support the show by:

- telling your friends.

- sharing this episode using the social sharing buttons below.

- subscribing to the show and leaving a rating and review in iTunes. Not sure how? Just follow these simple steps here or watch the short video tutorial, http://youtu.be/rq4OCyRGjHc?list=UUH3MfNZLXlKgionAs6kMT_Q

- subscribing to the show in Stitcher, http://www.stitcher.com/s?fid=54499&refid=stpr

Thanks so much for your support!

]]>If you have an event or class you would like to submit, send an email to [email protected] and I will send you the details I need for the press release.

OK, I’ll go in Alphabetic order here:

]]>

If you have an event or class you would like to submit, send an email to [email protected] and I will send you the details I need for the press release.

OK, I’ll go in Alphabetic order here:

]]>

If you have an event or class you would like to submit, send an email to [email protected] and I will send you the details I need for the press release.

If you have an event or class you would like to submit, send an email to [email protected] and I will send you the details I need for the press release.

]]>First I talk with Payne Anne Chassen and Sylvia Andrassy, they are in Pampano Beach, Florida for the FABA SE Regional meet. The meet was held at the Guild, a non-profit folk art school started by Shaun Williams and Sylvia Andrassy. Payne was demonstrating a corner shelf with antique glass bulbs incorporated into the design.

Then I talk to Dennis Dusek who was demonstrating garden tools at the Weaverville Hammer-in, this is held at the Jake Jackson Museum Weaverville, California. He walked around and spoke with the other demonstrators that were there, Monica Coyne, Brett Moten, Dan Perkins, Victoria Ritter and Mark Aspery.

Links:

Facebook page for FABA SE

]]>

First I talk with Payne Anne Chassen and Sylvia Andrassy, they are in Pampano Beach, Florida for the FABA SE Regional meet. The meet was held at the Guild, a non-profit folk art school started by Shaun Williams and Sylvia Andrassy. Payne was demonstrating a corner shelf with antique glass bulbs incorporated into the design.

Then I talk to Dennis Dusek who was demonstrating garden tools at the Weaverville Hammer-in, this is held at the Jake Jackson Museum Weaverville, California. He walked around and spoke with the other demonstrators that were there, Monica Coyne, Brett Moten, Dan Perkins, Victoria Ritter and Mark Aspery.

Links:

Facebook page for FABA SE

]]>

And they happen to be the sponsor for today’s episode. There is still time to get the early bird discount of $165 for all 3 days if you register before March 22nd. The demonstrator line-up is:

Zeevik Gottlieb, Lynda Metcalfe, Ellen Durkan, Haley Woodword, Colby Brinkman, David Lisch, Mark Aspery, Darryl Nelson and Paul Boulay.

To register, head over to www.calsmith.org and click on the events tab for the online registration button.

What We Talked About

- Dennis tells us about his past conferences that he has organized, the last one was in 2013 with an attendance of around 400 people.

- The core group of 4, Dennis, Paul, Dan and Victoria, meet weekly to go through a list of things that need attention. This happens for eight months ahead of the conference.

- Each person has a role; Paul Boulay works with the budget and the big picture ideas with Dennis, Victoria Ritter works with organizing the groups of vendors, volunteers and registration people, and Dan Perkins is the education site manager, helping with the layout of the venue and gathering/installing all of the equipment for the demonstrators and teaching tents.

- CBA will be purchasing 10 anvils, so they can have 10 forging stations at the conference for the attendees to use.

- We talk about the forging contests that will be held each night of the conference; forging a cube, forge anything from a railroad spike and a wearable art forged piece.

Guest Links

- Register for the conference - calsmith.org

And they happen to be the sponsor for today’s episode. There is still time to get the early bird discount of $165 for all 3 days if you register before March 22nd. The demonstrator line-up is:

Zeevik Gottlieb, Lynda Metcalfe, Ellen Durkan, Haley Woodword, Colby Brinkman, David Lisch, Mark Aspery, Darryl Nelson and Paul Boulay.

To register, head over to www.calsmith.org and click on the events tab for the online registration button.

What We Talked About

- Dennis tells us about his past conferences that he has organized, the last one was in 2013 with an attendance of around 400 people.

- The core group of 4, Dennis, Paul, Dan and Victoria, meet weekly to go through a list of things that need attention. This happens for eight months ahead of the conference.

- Each person has a role; Paul Boulay works with the budget and the big picture ideas with Dennis, Victoria Ritter works with organizing the groups of vendors, volunteers and registration people, and Dan Perkins is the education site manager, helping with the layout of the venue and gathering/installing all of the equipment for the demonstrators and teaching tents.

- CBA will be purchasing 10 anvils, so they can have 10 forging stations at the conference for the attendees to use.

- We talk about the forging contests that will be held each night of the conference; forging a cube, forge anything from a railroad spike and a wearable art forged piece.

Guest Links

- Register for the conference - calsmith.org

If you have an event or class you would like to submit, send an email to [email protected] and I will send you the details I need for the press release.

If you have an event or class you would like to submit, send an email to [email protected] and I will send you the details I need for the press release.

]]>

What We Talked About

- Hammer’s Blow, Volume 26 #1 article written by Dan Nauman titled “Picture That”. This addresses the importance of having good portfolio pictures early on in your career, even if you are a hobbyist.

- Riveting tips from Dorothy Steigler

- Penetrating Oils test from the Appalachian Blacksmiths Association newsletter of December 2012

A Big Thank You to today’s sponsor - Eureka Springs School of the Arts, http://essa-art.org/ or give them a call (479) 253-5384.

If you enjoyed this episode, I would love it if you would support the show by:

- telling your friends.

- sharing this episode using the social sharing buttons below.

- subscribing to the show and leaving a rating and review in iTunes. Not sure how? Just follow these simple steps here or watch the short video tutorial, http://youtu.be/rq4OCyRGjHc?list=UUH3MfNZLXlKgionAs6kMT_Q

- subscribing to the show in Stitcher, http://www.stitcher.com/s?fid=54499&refid=stpr

Thanks so much for your support!

]]>What We Talked About

- Hammer’s Blow, Volume 26 #1 article written by Dan Nauman titled “Picture That”. This addresses the importance of having good portfolio pictures early on in your career, even if you are a hobbyist.

- Riveting tips from Dorothy Steigler

- Penetrating Oils test from the Appalachian Blacksmiths Association newsletter of December 2012

A Big Thank You to today’s sponsor - Eureka Springs School of the Arts, http://essa-art.org/ or give them a call (479) 253-5384.

If you enjoyed this episode, I would love it if you would support the show by:

- telling your friends.

- sharing this episode using the social sharing buttons below.

- subscribing to the show and leaving a rating and review in iTunes. Not sure how? Just follow these simple steps here or watch the short video tutorial, http://youtu.be/rq4OCyRGjHc?list=UUH3MfNZLXlKgionAs6kMT_Q

- subscribing to the show in Stitcher, http://www.stitcher.com/s?fid=54499&refid=stpr

Thanks so much for your support!

]]>This week I’ve got Michael Whipps from Melbourne Australia, btw he goes by Whipps. He’s a metal worker who makes custom spherical firepits with his wife in Australia and he started blacksmithing about 6 months ago. The reason I have him on today is to talk about his new podcast “Metal Sculpture Show”. I think I’ve mentioned this before to you guys, I started a podcast network called The Burn Network, basically, it’s a collection of metalworking podcasts. The reason I started it was to encourage other blacksmith’s or metal workers to start their own podcasts and I would help them get started, show them the ropes of the podcast tech world, provide the hosting and continued support. To have a searchable network that offers relevant and different podcasts to our community of metal workers. So, Whipps contacted me 7 months ago about wanting to start a podcast on the network and have it be about metal art sculpture. We worked through the details of how this is a huge time consumer while being a labor of love for fellow artists, the equipment to work with, recording software, techniques of being a host of a show, etc and now, here we are talking about his podcast and his first 4 episodes that were just released a few days ago!

If anyone is interested in listening to the “master feed” of the Burn Network, just search for The Burn Network in your podcast apps, iTunes, Spotify and online at www.theburnnetwork.com. If anyone is interested in starting a podcast and wants to know more info on what it takes, drop me a line at [email protected].

What We Talked About

- Whips tells us why he wanted to start the podcast.

- The topic of making a living as an artist comes up and life/work balance vs money making

- Whipps describes his background that lead him to his metal working business called Whipps Designs, it involves mountain biking!

- He tells the story of buying his first anvil from a farmer who didn’t want to sell it.

Guest Links

- Whipps Designs website - whippsdesigns.com.au

- Podcast website – metalsculptureshow.com

- Instagram - @metalsculptureshow

- And on Facebook

If you enjoyed this episode, I would love it if you would support the show by:

- telling your friends.

- sharing this episode using the social sharing buttons below.

- subscribing to the show and leaving a rating and review in iTunes. Not sure how? Just follow these simple steps here or watch the short video tutorial, http://youtu.be/rq4OCyRGjHc?list=UUH3MfNZLXlKgionAs6kMT_Q

- subscribing to the show in Stitcher, http://www.stitcher.com/s?fid=54499&refid=stpr

Thanks so much for your support!

]]>

This week I’ve got Michael Whipps from Melbourne Australia, btw he goes by Whipps. He’s a metal worker who makes custom spherical firepits with his wife in Australia and he started blacksmithing about 6 months ago. The reason I have him on today is to talk about his new podcast “Metal Sculpture Show”. I think I’ve mentioned this before to you guys, I started a podcast network called The Burn Network, basically, it’s a collection of metalworking podcasts. The reason I started it was to encourage other blacksmith’s or metal workers to start their own podcasts and I would help them get started, show them the ropes of the podcast tech world, provide the hosting and continued support. To have a searchable network that offers relevant and different podcasts to our community of metal workers. So, Whipps contacted me 7 months ago about wanting to start a podcast on the network and have it be about metal art sculpture. We worked through the details of how this is a huge time consumer while being a labor of love for fellow artists, the equipment to work with, recording software, techniques of being a host of a show, etc and now, here we are talking about his podcast and his first 4 episodes that were just released a few days ago!

If anyone is interested in listening to the “master feed” of the Burn Network, just search for The Burn Network in your podcast apps, iTunes, Spotify and online at www.theburnnetwork.com. If anyone is interested in starting a podcast and wants to know more info on what it takes, drop me a line at [email protected].

What We Talked About

- Whips tells us why he wanted to start the podcast.

- The topic of making a living as an artist comes up and life/work balance vs money making

- Whipps describes his background that lead him to his metal working business called Whipps Designs, it involves mountain biking!

- He tells the story of buying his first anvil from a farmer who didn’t want to sell it.

Guest Links

- Whipps Designs website - whippsdesigns.com.au

- Podcast website – metalsculptureshow.com

- Instagram - @metalsculptureshow

- And on Facebook

If you enjoyed this episode, I would love it if you would support the show by:

- telling your friends.

- sharing this episode using the social sharing buttons below.

- subscribing to the show and leaving a rating and review in iTunes. Not sure how? Just follow these simple steps here or watch the short video tutorial, http://youtu.be/rq4OCyRGjHc?list=UUH3MfNZLXlKgionAs6kMT_Q

- subscribing to the show in Stitcher, http://www.stitcher.com/s?fid=54499&refid=stpr

Thanks so much for your support!

]]>

And that brings us to our sponsor for today’s episode and that’s the 2018 CBA Spring Conference organizers.

To register, head over to www.calsmith.org and click on the events tab for the online registration button.

What We Talked About

- While Haley was in college when he took a sculpture class with a metal working component, after making several welded sculptures he searched for a blacksmithing college program to further his metal working skills. He found that Austin Community College offered a few blacksmith classes and moved to Austin for enrollment.

- Haley and Colby met on a college field trip to Mexico, actually a 37-hour bus ride to Santa Clara Del Cobre, Mexico for a 3-week copper smithing course.

- Colby’s background also started with taking classes at the Austin Community College in 1995.

- Colby spent 2 years in Europe as a blacksmith apprentice, specifically with Joseph Muck in the Czech Republic, Sebastian Fisher in Spain and Claudio Bottero in Italy.

- Haley and Colby talk about how the Austin Metal Authority started, basically because they needed a name for a studio tour they participated in.

- The Austin Forging Competition is an annual event that Haley and Colby started in their Austin Metal Authority shop, they talk about how it has now moved to the Mobile Loaves Community site and has about 1000 attendees.

Guest Links

- Ernst Heinrich Haeckel “Art Forms in Nature” book on Amazon - https://www.amazon.com/Forms-Nature-Dover-Pictorial-Archive/dp/0486229874/ref=pd_bxgy_14_img_3?_encoding=UTF8&pd_rd_i=0486229874&pd_rd_r=01ZJJZGQ0DTFXCPY9ADB&pd_rd_w=IOZy7&pd_rd_wg=TCpO3&psc=1&refRID=01ZJJZGQ0DTFXCPY9ADB

- Colby Brinkman Website – metalmantis.com

- Haley Woodward Website – haleywoodward.com

- The Devil’s Blacksmith Documentary -- https://www.indiegogo.com/projects/the-devil-s-blacksmith-documentary-arts--2#/

And that brings us to our sponsor for today’s episode and that’s the 2018 CBA Spring Conference organizers.

To register, head over to www.calsmith.org and click on the events tab for the online registration button.

What We Talked About

- While Haley was in college when he took a sculpture class with a metal working component, after making several welded sculptures he searched for a blacksmithing college program to further his metal working skills. He found that Austin Community College offered a few blacksmith classes and moved to Austin for enrollment.

- Haley and Colby met on a college field trip to Mexico, actually a 37-hour bus ride to Santa Clara Del Cobre, Mexico for a 3-week copper smithing course.

- Colby’s background also started with taking classes at the Austin Community College in 1995.

- Colby spent 2 years in Europe as a blacksmith apprentice, specifically with Joseph Muck in the Czech Republic, Sebastian Fisher in Spain and Claudio Bottero in Italy.

- Haley and Colby talk about how the Austin Metal Authority started, basically because they needed a name for a studio tour they participated in.

- The Austin Forging Competition is an annual event that Haley and Colby started in their Austin Metal Authority shop, they talk about how it has now moved to the Mobile Loaves Community site and has about 1000 attendees.

Guest Links

- Ernst Heinrich Haeckel “Art Forms in Nature” book on Amazon - https://www.amazon.com/Forms-Nature-Dover-Pictorial-Archive/dp/0486229874/ref=pd_bxgy_14_img_3?_encoding=UTF8&pd_rd_i=0486229874&pd_rd_r=01ZJJZGQ0DTFXCPY9ADB&pd_rd_w=IOZy7&pd_rd_wg=TCpO3&psc=1&refRID=01ZJJZGQ0DTFXCPY9ADB

- Colby Brinkman Website – metalmantis.com

- Haley Woodward Website – haleywoodward.com

- The Devil’s Blacksmith Documentary -- https://www.indiegogo.com/projects/the-devil-s-blacksmith-documentary-arts--2#/

If you have an event or class you would like to submit, send an email to [email protected] and I will send you the details I need for the press release.

If you have an event or class you would like to submit, send an email to [email protected] and I will send you the details I need for the press release.

]]>To register, head over to www.calsmith.org and click on the events tab for the online conference registration button.

What We Talked About

- Ellen is teaching drawing, 3D design and sculpture as an adjunct professor at the Delaware College of Art and Design.

- Besides teaching at the college, she is preparing for a performance style runway show of her iron fashion dresses in November. She is planning on having 15 to 20 models as well as a few aerial performers.

- Ellen tells us about her photo shoots with a professional photographer who is her friend, Joe, and how they come up with ideas for photographing Ellen’s iron fashion pieces.

- Ellen is teaching and demonstrating more for 2018, she’ll be in California, New Jersey, Virginia, New York and Buenos Aires Argentina.

- Ellen has an exhibition of her large-scale drawings that will be held at the Delaware Art Museum

- Also, she was recently awarded a $6000 art grant to help her put on her forged fashion runway show in November. The grant came from the Delaware Division of the Arts.

Guest Links

- Ellen’s website - http://www.ellendurkan.com/

- Peter’s Valley workshop - http://www.petersvalleyworkshops.bigcartel.com/product/fitting-forming-wearable-bustiers-and-chest-pieces

- Banton-Smith Center for Blacksmith and Metal Arts facebook page - https://www.facebook.com/BantonSmithCenter/

- Rochester Arc and Flame Center - https://www.rocafc.com/collections/blacksmithing-technique-blacksmithing/products/blacksmithing-workshop-5-days-with-ellen-durkan

To register, head over to www.calsmith.org and click on the events tab for the online conference registration button.

What We Talked About

- Ellen is teaching drawing, 3D design and sculpture as an adjunct professor at the Delaware College of Art and Design.

- Besides teaching at the college, she is preparing for a performance style runway show of her iron fashion dresses in November. She is planning on having 15 to 20 models as well as a few aerial performers.

- Ellen tells us about her photo shoots with a professional photographer who is her friend, Joe, and how they come up with ideas for photographing Ellen’s iron fashion pieces.

- Ellen is teaching and demonstrating more for 2018, she’ll be in California, New Jersey, Virginia, New York and Buenos Aires Argentina.

- Ellen has an exhibition of her large-scale drawings that will be held at the Delaware Art Museum

- Also, she was recently awarded a $6000 art grant to help her put on her forged fashion runway show in November. The grant came from the Delaware Division of the Arts.

Guest Links

- Ellen’s website - http://www.ellendurkan.com/

- Peter’s Valley workshop - http://www.petersvalleyworkshops.bigcartel.com/product/fitting-forming-wearable-bustiers-and-chest-pieces

- Banton-Smith Center for Blacksmith and Metal Arts facebook page - https://www.facebook.com/BantonSmithCenter/

- Rochester Arc and Flame Center - https://www.rocafc.com/collections/blacksmithing-technique-blacksmithing/products/blacksmithing-workshop-5-days-with-ellen-durkan

Now I’d like to take the time to thank our sponsors for today’s episode and that’s the Eureka Springs School of the Arts, aka ESSA. It’s a non-profit school located in Eureka Springs, Arkansas. This year, they are celebrating 20 years of teaching the arts! To see the complete list of classes for 2018, visit the website, http://essa-art.org/ or give them a call (479) 253-5384.

OK, here is the article titled “An American Blacksmith in Cuba” by Serene Silva.

]]>Now I’d like to take the time to thank our sponsors for today’s episode and that’s the Eureka Springs School of the Arts, aka ESSA. It’s a non-profit school located in Eureka Springs, Arkansas. This year, they are celebrating 20 years of teaching the arts! To see the complete list of classes for 2018, visit the website, http://essa-art.org/ or give them a call (479) 253-5384.

OK, here is the article titled “An American Blacksmith in Cuba” by Serene Silva.

]]>What We Talked About

- David now fills most of his time making high-end award-winning knives and teaching classes which fill up in 1 to 2 days after posting.

- He used to have a shop and school in Seattle for 15 years where he textured metal for Nordstrom’s and other companies.

- When marijuana became legal in Washington state, the warehouse spaces quickly became grow houses and in turn, the rents were raised and warehouses for rent were hard to find.

- The increase in David’s rent from $2500 to $3200 eventually made him move out and buy a property that had both a house and shop space.

- These days David is incorporating his sculptural side of blacksmithing to his blades. He recently sold a frog (for $10k) with a dagger coming out of his throat and a Damascus dragonfly on his tongue.

- David was introduced to Damascus at one of his friend’s shops, where a few blacksmiths got together and made some damascus. Then at one of the NWBA (North West Blacksmith Association) annual conferences, he traded a hammer he made for some Damascus making stock. He started making Damascus before he ever made a blade!

- His first knife making class was from Bob Kramer in 2006.

- After joining the American Bladesmith Society he became an apprentice bladesmith, then passed his journeyman smith certification, then 5 years later passed his master smith certification.

- In his shop, he has 330lb Wolf Air hammer, 165 lb Wolf air hammer, 3 hydraulic presses, 10 grinders and 10 anvils.

- He has been a member of the NWBA for over 20 years and he and his wife have served on the board for 4 years.

- David will be demonstrating at the upcoming CBA Spring Conference and he will demo knife making for beginners (staghorn small knife with a 4 in blade) and have separate demonstrations for intermediate and expert knife makers. Including pinning on a wood handle for a kitchen knife, shaping guards and finishing techniques.

- He makes all of his own gas forges, they are 1 burner venture forges made from cut up oxygen tanks, 11 inches long. He says it’s very important to coat the Kaowool inside your forge with a refractory castable cement. He uses Mizzou castable in his forges, you can find it online.

Guest Links

- Website - http://www.davidlisch.com/index.html

- Instagram - @davidlisch

- American Bladesmith Society Website - http://www.americanbladesmith.com/

A Big Thank You to today’s sponsor – CBA Spring Conference, www.calsmith.org

If you enjoyed this episode, I would love it if you would support the show by:

- telling your friends.

- sharing this episode using the social sharing buttons below.

- subscribing to the show and leaving a rating and review in iTunes. Not sure how? Just follow these simple steps here or watch the short video tutorial, http://youtu.be/rq4OCyRGjHc?list=UUH3MfNZLXlKgionAs6kMT_Q

- subscribing to the show in Stitcher, http://www.stitcher.com/s?fid=54499&refid=stpr

Thanks so much for your support!

]]>What We Talked About

- David now fills most of his time making high-end award-winning knives and teaching classes which fill up in 1 to 2 days after posting.

- He used to have a shop and school in Seattle for 15 years where he textured metal for Nordstrom’s and other companies.

- When marijuana became legal in Washington state, the warehouse spaces quickly became grow houses and in turn, the rents were raised and warehouses for rent were hard to find.

- The increase in David’s rent from $2500 to $3200 eventually made him move out and buy a property that had both a house and shop space.

- These days David is incorporating his sculptural side of blacksmithing to his blades. He recently sold a frog (for $10k) with a dagger coming out of his throat and a Damascus dragonfly on his tongue.

- David was introduced to Damascus at one of his friend’s shops, where a few blacksmiths got together and made some damascus. Then at one of the NWBA (North West Blacksmith Association) annual conferences, he traded a hammer he made for some Damascus making stock. He started making Damascus before he ever made a blade!

- His first knife making class was from Bob Kramer in 2006.

- After joining the American Bladesmith Society he became an apprentice bladesmith, then passed his journeyman smith certification, then 5 years later passed his master smith certification.

- In his shop, he has 330lb Wolf Air hammer, 165 lb Wolf air hammer, 3 hydraulic presses, 10 grinders and 10 anvils.

- He has been a member of the NWBA for over 20 years and he and his wife have served on the board for 4 years.

- David will be demonstrating at the upcoming CBA Spring Conference and he will demo knife making for beginners (staghorn small knife with a 4 in blade) and have separate demonstrations for intermediate and expert knife makers. Including pinning on a wood handle for a kitchen knife, shaping guards and finishing techniques.

- He makes all of his own gas forges, they are 1 burner venture forges made from cut up oxygen tanks, 11 inches long. He says it’s very important to coat the Kaowool inside your forge with a refractory castable cement. He uses Mizzou castable in his forges, you can find it online.

Guest Links

- Website - http://www.davidlisch.com/index.html

- Instagram - @davidlisch

- American Bladesmith Society Website - http://www.americanbladesmith.com/

A Big Thank You to today’s sponsor – CBA Spring Conference, www.calsmith.org

If you enjoyed this episode, I would love it if you would support the show by:

- telling your friends.

- sharing this episode using the social sharing buttons below.

- subscribing to the show and leaving a rating and review in iTunes. Not sure how? Just follow these simple steps here or watch the short video tutorial, http://youtu.be/rq4OCyRGjHc?list=UUH3MfNZLXlKgionAs6kMT_Q

- subscribing to the show in Stitcher, http://www.stitcher.com/s?fid=54499&refid=stpr

Thanks so much for your support!

]]>If you have an event or class you would like to submit, send an email to [email protected] and I will send you the details I need for the press release.

This year is the bi-annual ABANA conference which will be held in Richmond Virginia June 27th – 30th, registration is open on the abana.org website.

Also, this year’s CBA Spring conference is held in Placerville, CA, just outside of Sacramento, the dates are April 12th – 14th and registration just opened on their website, www.calsmith.org, this year it’s $180 for the 3-day event.

As of Jan 1 Haystack Mountain School of Crafts, application process opens for the two blacksmith summer sessions they will be holding. The two classes are: on June 10th Patrick Quinn is teaching "Thinking Big, Working Small", it’s a 2 week session. Workshop students will explore sculptural forms through forged, riveted, and mechanically fastened parts. Working with thin gauge plate and other small-scale industrial materials, focus and emphasis will be placed on creating small-scale sculptural pieces using joinery techniques, paired with inspiration from large-scale public works.

June 24-July 6, 2018 , Marc Maiorana, Heirloom Iron This workshop will teach students to create ironwares for the home that will stand the test of time.

DEADLINES:

March 1 for applicants seeking scholarship support for a workshop

April 1 for general workshop applications

Adam's Forge is a non-profit org founded in 2002. This organization offers a regular schedule of blacksmith and metalworking classes. They are starting a fundraising campaign to build a new forge home at the Heritage Square Museum in Los Angeles. This is a call for art from all the blacksmiths out there to help raise funds for the relocation and the new smithy building. They are hosting a one day annual festival for the public on Sunday, February 18th. You can donate hand-forged items that they can sell at the festival, be sure to add your touch mark and send it in before the end of January. Mail your metal donations to Adam's Forge at 2640 North San Fernando Rd, Los Angeles, CA 90065. This info will be in the show notes of this episode as well.

They are also accepting cash donations and another donor has stepped up to match dollar for dollar donations, up to $5000!

All of the details are on the Adam's Forge website which is www.adamsforge.org

If you have an event or class you would like to submit, send an email to [email protected] and I will send you the details I need for the press release.

This year is the bi-annual ABANA conference which will be held in Richmond Virginia June 27th – 30th, registration is open on the abana.org website.

Also, this year’s CBA Spring conference is held in Placerville, CA, just outside of Sacramento, the dates are April 12th – 14th and registration just opened on their website, www.calsmith.org, this year it’s $180 for the 3-day event.

As of Jan 1 Haystack Mountain School of Crafts, application process opens for the two blacksmith summer sessions they will be holding. The two classes are: on June 10th Patrick Quinn is teaching "Thinking Big, Working Small", it’s a 2 week session. Workshop students will explore sculptural forms through forged, riveted, and mechanically fastened parts. Working with thin gauge plate and other small-scale industrial materials, focus and emphasis will be placed on creating small-scale sculptural pieces using joinery techniques, paired with inspiration from large-scale public works.

June 24-July 6, 2018 , Marc Maiorana, Heirloom Iron This workshop will teach students to create ironwares for the home that will stand the test of time.

DEADLINES:

March 1 for applicants seeking scholarship support for a workshop

April 1 for general workshop applications

Adam's Forge is a non-profit org founded in 2002. This organization offers a regular schedule of blacksmith and metalworking classes. They are starting a fundraising campaign to build a new forge home at the Heritage Square Museum in Los Angeles. This is a call for art from all the blacksmiths out there to help raise funds for the relocation and the new smithy building. They are hosting a one day annual festival for the public on Sunday, February 18th. You can donate hand-forged items that they can sell at the festival, be sure to add your touch mark and send it in before the end of January. Mail your metal donations to Adam's Forge at 2640 North San Fernando Rd, Los Angeles, CA 90065. This info will be in the show notes of this episode as well. They are also accepting cash donations and another donor has stepped up to match dollar for dollar donations, up to $5000! All of the details are on the Adam's Forge website which is www.adamsforge.org .

]]>This week I’ve got Evan Wilson from Austin, Texas who is the program director for the blacksmith shop at this nonprofit community organization called Mobile Loaves and Fishes. The Community Forge & Woodshop empowers their community of homeless members to engage in the creation of timeless crafts while also earning a dignified income. Through blacksmithing, woodworking and a range of other projects, the men and women in this Community Works program become part of a restorative journey toward social contribution, financial stability and a mastery of handcrafting skills.

Their craftsmen and artists receive 100% of the profit from the sale of their products, enabling them to become more settled and experience greater stability in Community First! Village. They also encounter a greater sense of purpose, healing, and friendships — foundational components of life that every person needs and deserves.

What We Talked About

- Evan talks about his experience being a striker for Claudio Bottero at the Florida Artist Blacksmith Association in October 2017, “like drinking from a fire hose”.

- Mobile Loaves and Fishes is a nonprofit organization in Austin that started 19 years ago, they help feed and cloth the homeless population.

- The organization decided to build their own RV park to house the homeless and start a community centered program on 27 acres with 250 housing units.

- Within the community they have programs for the members to attend and learn form such as: animal husbandry, ceramics, glass blowing, leatherwork, painting, woodworking and blacksmithing.

- These programs provide a way to learn how to earn a dignified income, alternative economy. The community has a market and gift shop where they sell the wares of the members.

- Evan talks about his nonprofit background and how he worked for one in Afghanistan teaching English and helping with a Maternal and Infant Mortality program.

- He mentions his “Metal Mother” Dawn Raines (the Welding and Blacksmith director at Austin Community College) who taught him a lot in the beginning of his blacksmithing venture. Haley Woodward is another mentor he mentions who took him under his wing and helped a tremendous amount in building the community blacksmith program at Mobile Loaves and Fishes.

- Evan has now taken the reins of organizing the Austin Forging Competition that started in 2010. It used to be held at the Austin Forging Authority (Haley Woodward and Colby Brinkman’s Shop) and in 2015 Evan mentioned they should hold it at the community Works workshop.

Guest Links

- Mobile Loaves and Fishes community Works Program link - - https://mlf.org/community-works/

- Instagram: @mobileloaves_communityforge

If you enjoyed this episode, I would love it if you would support the show by:

- telling your friends.

- sharing this episode using the social sharing buttons below.

- subscribing to the show and leaving a rating and review in iTunes. Not sure how? Just follow these simple steps here or watch the short video tutorial, http://youtu.be/rq4OCyRGjHc?list=UUH3MfNZLXlKgionAs6kMT_Q

- subscribing to the show in Stitcher, http://www.stitcher.com/s?fid=54499&refid=stpr

Thanks so much for your support!

]]>This week I’ve got Evan Wilson from Austin, Texas who is the program director for the blacksmith shop at this nonprofit community organization called Mobile Loaves and Fishes. The Community Forge & Woodshop empowers their community of homeless members to engage in the creation of timeless crafts while also earning a dignified income. Through blacksmithing, woodworking and a range of other projects, the men and women in this Community Works program become part of a restorative journey toward social contribution, financial stability and a mastery of handcrafting skills.

Their craftsmen and artists receive 100% of the profit from the sale of their products, enabling them to become more settled and experience greater stability in Community First! Village. They also encounter a greater sense of purpose, healing, and friendships — foundational components of life that every person needs and deserves.

What We Talked About

- Evan talks about his experience being a striker for Claudio Bottero at the Florida Artist Blacksmith Association in October 2017, “like drinking from a fire hose”.

- Mobile Loaves and Fishes is a nonprofit organization in Austin that started 19 years ago, they help feed and cloth the homeless population.

- The organization decided to build their own RV park to house the homeless and start a community centered program on 27 acres with 250 housing units.

- Within the community they have programs for the members to attend and learn form such as: animal husbandry, ceramics, glass blowing, leatherwork, painting, woodworking and blacksmithing.

- These programs provide a way to learn how to earn a dignified income, alternative economy. The community has a market and gift shop where they sell the wares of the members.

- Evan talks about his nonprofit background and how he worked for one in Afghanistan teaching English and helping with a Maternal and Infant Mortality program.

- He mentions his “Metal Mother” Dawn Raines (the Welding and Blacksmith director at Austin Community College) who taught him a lot in the beginning of his blacksmithing venture. Haley Woodward is another mentor he mentions who took him under his wing and helped a tremendous amount in building the community blacksmith program at Mobile Loaves and Fishes.

- Evan has now taken the reins of organizing the Austin Forging Competition that started in 2010. It used to be held at the Austin Forging Authority (Haley Woodward and Colby Brinkman’s Shop) and in 2015 Evan mentioned they should hold it at the community Works workshop.

Guest Links

- Mobile Loaves and Fishes community Works Program link - - https://mlf.org/community-works/

- Instagram: @mobileloaves_communityforge

If you enjoyed this episode, I would love it if you would support the show by:

- telling your friends.

- sharing this episode using the social sharing buttons below.

- subscribing to the show and leaving a rating and review in iTunes. Not sure how? Just follow these simple steps here or watch the short video tutorial, http://youtu.be/rq4OCyRGjHc?list=UUH3MfNZLXlKgionAs6kMT_Q

- subscribing to the show in Stitcher, http://www.stitcher.com/s?fid=54499&refid=stpr

Thanks so much for your support!

]]>What We Talked About

- This FABA Conference that was held in the last weekend in October of 2017, had the highest attendance ever in FABA’s entire history with 450 attendees.

- The conference had 6 specialty workshops and two demonstrator workshops by Lisa Johnson and Claudio Bottero.

- Shaun talks about his visit to Claudio’s blacksmith shop in Italy.

- Sylvia tells us about her beginnings in blacksmithing 3 years ago and when Shaun asked her to go to a blacksmith conference as a date!

- Dark Angel Armory and Forge is Shaun’s forging business, he also started teaching beginner blacksmithing and knife making classes from this location. The classes grew so fast that Shaun and Sylvia decided to start a Guild Folk Art School offering different types of “medieval” art classes; leatherworking, ceramics, jewelry making. The classes are booked 3 to 4 months in advance.

- The Guild also offers a monthly “membership” to the students who have taken previous classes.

- They recommend an inspiring artistic Italian blacksmith book, “La Magia de Febrero del Tutto Italiano Centro Fabra Milidia” or “The Magic of Italian Forged Artist, 100 Artist 1000 Ideas”

Links

- Florida Artist Blacksmith Association – blacksmithing.org

- The Guild Urban Craft and Folk-art school - https://www.guildfl.com/

- Dark Angel Armory and Forge – https://www.darkangelarmory.com/

If you enjoyed this episode, I would love it if you would support the show by:

- telling your friends.

- sharing this episode using the social sharing buttons below.

- subscribing to the show and leaving a rating and review in iTunes. Not sure how? Just follow these simple steps here or watch the short video tutorial, http://youtu.be/rq4OCyRGjHc?list=UUH3MfNZLXlKgionAs6kMT_Q

- subscribing to the show in Stitcher, http://www.stitcher.com/s?fid=54499&refid=stpr

Thanks so much for your support!

]]>What We Talked About

- This FABA Conference that was held in the last weekend in October of 2017, had the highest attendance ever in FABA’s entire history with 450 attendees.

- The conference had 6 specialty workshops and two demonstrator workshops by Lisa Johnson and Claudio Bottero.

- Shaun talks about his visit to Claudio’s blacksmith shop in Italy.

- Sylvia tells us about her beginnings in blacksmithing 3 years ago and when Shaun asked her to go to a blacksmith conference as a date!

- Dark Angel Armory and Forge is Shaun’s forging business, he also started teaching beginner blacksmithing and knife making classes from this location. The classes grew so fast that Shaun and Sylvia decided to start a Guild Folk Art School offering different types of “medieval” art classes; leatherworking, ceramics, jewelry making. The classes are booked 3 to 4 months in advance.

- The Guild also offers a monthly “membership” to the students who have taken previous classes.

- They recommend an inspiring artistic Italian blacksmith book, “La Magia de Febrero del Tutto Italiano Centro Fabra Milidia” or “The Magic of Italian Forged Artist, 100 Artist 1000 Ideas”

Links

- Florida Artist Blacksmith Association – blacksmithing.org

- The Guild Urban Craft and Folk-art school - https://www.guildfl.com/

- Dark Angel Armory and Forge – https://www.darkangelarmory.com/

If you enjoyed this episode, I would love it if you would support the show by:

- telling your friends.

- sharing this episode using the social sharing buttons below.

- subscribing to the show and leaving a rating and review in iTunes. Not sure how? Just follow these simple steps here or watch the short video tutorial, http://youtu.be/rq4OCyRGjHc?list=UUH3MfNZLXlKgionAs6kMT_Q

- subscribing to the show in Stitcher, http://www.stitcher.com/s?fid=54499&refid=stpr

Thanks so much for your support!

]]>I’ve never thought about it and Mike Mumford says he’s never thought about it either, so he went out to his shop and found that most of his tongs are right-handed, but found two bolt tongs that are left-handed. So, I too, went to my shop to see what I owned. I have 6 pairs of right-handed tongs made by Dennis Dusek, a few random tailgate pairs that are right handed and only two that are left-handed. Those two were made and given to me by Uri Hofi and Zeevik Gottlieb.

Here is what the article by Mike said:

- First, some really confusing terminology: The handedness of the tongs refers to the comfortable fit when held in your non-dominant hand.

- A right-handed person would hold right-handed tongs in their left, non-dominant hand.

- Right-handed tongs are designed to work best for a right-handed person.

- Start with the idea that the upper rein is held against the thumb and palm, while the fingers hold the lower rein.

- The more comfortable way to hold and release is that the lower rein is closer to the body, away from the palm. The lower rein naturally drops away as the fingers are released.

- The picture below shows right-handed tongs to be held in the left hand on top. Below them are left-handed tongs to be held in the right hand.

I’ve never thought about it and Mike Mumford says he’s never thought about it either, so he went out to his shop and found that most of his tongs are right-handed, but found two bolt tongs that are left-handed. So, I too, went to my shop to see what I owned. I have 6 pairs of right-handed tongs made by Dennis Dusek, a few random tailgate pairs that are right handed and only two that are left-handed. Those two were made and given to me by Uri Hofi and Zeevik Gottlieb.

Here is what the article by Mike said:

- First, some really confusing terminology: The handedness of the tongs refers to the comfortable fit when held in your non-dominant hand.

- A right-handed person would hold right-handed tongs in their left, non-dominant hand.

- Right-handed tongs are designed to work best for a right-handed person.

- Start with the idea that the upper rein is held against the thumb and palm, while the fingers hold the lower rein.

- The more comfortable way to hold and release is that the lower rein is closer to the body, away from the palm. The lower rein naturally drops away as the fingers are released.

- The picture below shows right-handed tongs to be held in the left hand on top. Below them are left-handed tongs to be held in the right hand.

If you have an event or class you would like to submit, send an email to [email protected] and I will send you the details I need for the press release.

I have to apologize for not releasing this on Nov 1st, 5 days ago. I was visiting my family in Virginia Beach and before that, I attended the FABA conference in Ocala Florida watching the incredibly talented master blacksmith and sculptor Claudio Bottero who is from Italy.

- The conference began on Oct 27th and ended on the 29th and the demonstrators were Claudio Bottero, Lisa Johnson, a jewelry/metalsmithing director at an art center in Florida and Sam Salvati, a bladesmith from Maryland.

- It was so magical to watch Claudio and his son Massimiliano, aka Massy, forge an incredible human figure sitting on a throne. The whole sculpture ended up being about 5 ft tall.

- Claudio worked with strikers the whole time, using many different sized top and bottom fullers to shape the legs, head, face, arms and hands.

- In fact a lot of the fullers he was using (maybe a set of 10 sizes) were made by Dennis Dusek, who was there striking for him, along with others. Dennis has a great system for these fullers, he forges custom tongs that hold all 10 different sized inset fullers. You can private message him on Facebook or Instagram, Dennis Dusek.

- Sunday, Claudio taught a 6-hour masters class to 6 lucky students who were handpicked for the class. He taught them how to forge a hand and a finger. Anyone at the conference could watch the class, and see the progress of each of the students.

- One thing I picked up on was how Claudio always dunked his long-handled wire brush in water before he brushed the hot piece. He explained that the steam produced popped off the scale faster while brushing. I will be trying this because the end result was really clean metal.

- If you want to hear more about the conference, I’ll be having Shaun Williams, the conference coordinator, on the show soon, a little something to look forward to. But if you want some instant gratification head over to the FABA facebook page for pics and videos of the conference.

Now onto the first announcement which is a special announcement about a possible upcoming Tire Hammer Building class, this announcement is to see much interest there would be for this class. Let me tell you the scoop and then you can decide if you would like to attend it:

Tire Hammer Build class instructed by Clay Spencer

The dates would be April 19th-22nd, with a pre-work session on the weekend preceding the workshop, they are shooting for about 12-15 participants with everyone leaving with a finished hammer

Held in Troy Ohio at the SOFA facility

Approximate cost $1500

If interested contact Mike Brennan at [email protected] by November 30th

Details will be available soon on the SOFA website at https://sofablacksmiths.org/

Payment should NOT be sent at this time. Just an email to express interest.

If you have an event or class you would like to submit, send an email to [email protected] and I will send you the details I need for the press release.

I have to apologize for not releasing this on Nov 1st, 5 days ago. I was visiting my family in Virginia Beach and before that, I attended the FABA conference in Ocala Florida watching the incredibly talented master blacksmith and sculptor Claudio Bottero who is from Italy.

- The conference began on Oct 27th and ended on the 29th and the demonstrators were Claudio Bottero, Lisa Johnson, a jewelry/metalsmithing director at an art center in Florida and Sam Salvati, a bladesmith from Maryland.

- It was so magical to watch Claudio and his son Massimiliano, aka Massy, forge an incredible human figure sitting on a throne. The whole sculpture ended up being about 5 ft tall.

- Claudio worked with strikers the whole time, using many different sized top and bottom fullers to shape the legs, head, face, arms and hands.

- In fact a lot of the fullers he was using (maybe a set of 10 sizes) were made by Dennis Dusek, who was there striking for him, along with others. Dennis has a great system for these fullers, he forges custom tongs that hold all 10 different sized inset fullers. You can private message him on Facebook or Instagram, Dennis Dusek.

- Sunday, Claudio taught a 6-hour masters class to 6 lucky students who were handpicked for the class. He taught them how to forge a hand and a finger. Anyone at the conference could watch the class, and see the progress of each of the students.

- One thing I picked up on was how Claudio always dunked his long-handled wire brush in water before he brushed the hot piece. He explained that the steam produced popped off the scale faster while brushing. I will be trying this because the end result was really clean metal.

- If you want to hear more about the conference, I’ll be having Shaun Williams, the conference coordinator, on the show soon, a little something to look forward to. But if you want some instant gratification head over to the FABA facebook page for pics and videos of the conference.

Now onto the first announcement which is a special announcement about a possible upcoming Tire Hammer Building class, this announcement is to see much interest there would be for this class. Let me tell you the scoop and then you can decide if you would like to attend it:

Tire Hammer Build class instructed by Clay Spencer

The dates would be April 19th-22nd, with a pre-work session on the weekend preceding the workshop, they are shooting for about 12-15 participants with everyone leaving with a finished hammer

Held in Troy Ohio at the SOFA facility

Approximate cost $1500

If interested contact Mike Brennan at [email protected] by November 30th

Details will be available soon on the SOFA website at https://sofablacksmiths.org/

Payment should NOT be sent at this time. Just an email to express interest.

]]>What We Talked About

- Larry talks about the days when he worked at PECO and would go down to the blacksmith shop on the property with Emmert while they both practiced blacksmithing.

- Larry was very good friends with Emmert and he was asked to write and read a eulogy at Emmert’s funeral. Larry reads it for us.

- How the name Quad State Round-up came to be.

- SOFA’s workshops have been very productive, they’ve made several projects for the City of Troy such a bell hanger for the cast iron City bell tower and a floodgate.

- I asked Larry what were some of the challenges they had starting a club and conferences back then in the late 70’s.

- In 1981, when SOFA was started, the membership dues were $6 per year!

- The first formal Quad State Round was in 1977 with Francis Whitaker, Dimitri Gerakaris, Eric Mobeous. There were 100 attendees with a $10 ticket.

- Emmert and Larry would decide who the demonstrators would be for the first few years and they also made all the food for the attendees. The first year they made 80 gallons of stew.

- Steve Roth has been another instrumental member that has put a lot of effort and time into organizing the Round-ups for the past 15 years.

- We talk about the best things that keep members coming back for more within the SOFA club and the conferences.

Guest Links

- SOFA website - https://sofablacksmiths.org/

- Victoria Patti’s YouTube channel for Blacksmither Radio - https://www.youtube.com/user/MissSweetVP/feed

If you enjoyed this episode, I would love it if you would support the show by:

- telling your friends.

- sharing this episode using the social sharing buttons below.

- subscribing to the show and leaving a rating and review in iTunes. Not sure how? Just follow these simple steps here or watch the short video tutorial, http://youtu.be/rq4OCyRGjHc?list=UUH3MfNZLXlKgionAs6kMT_Q

- subscribing to the show in Stitcher, http://www.stitcher.com/s?fid=54499&refid=stpr

Thanks so much for your support!

]]>What We Talked About

- Larry talks about the days when he worked at PECO and would go down to the blacksmith shop on the property with Emmert while they both practiced blacksmithing.

- Larry was very good friends with Emmert and he was asked to write and read a eulogy at Emmert’s funeral. Larry reads it for us.

- How the name Quad State Round-up came to be.

- SOFA’s workshops have been very productive, they’ve made several projects for the City of Troy such a bell hanger for the cast iron City bell tower and a floodgate.

- I asked Larry what were some of the challenges they had starting a club and conferences back then in the late 70’s.

- In 1981, when SOFA was started, the membership dues were $6 per year!

- The first formal Quad State Round was in 1977 with Francis Whitaker, Dimitri Gerakaris, Eric Mobeous. There were 100 attendees with a $10 ticket.

- Emmert and Larry would decide who the demonstrators would be for the first few years and they also made all the food for the attendees. The first year they made 80 gallons of stew.

- Steve Roth has been another instrumental member that has put a lot of effort and time into organizing the Round-ups for the past 15 years.

- We talk about the best things that keep members coming back for more within the SOFA club and the conferences.

Guest Links

- SOFA website - https://sofablacksmiths.org/

- Victoria Patti’s YouTube channel for Blacksmither Radio - https://www.youtube.com/user/MissSweetVP/feed

If you enjoyed this episode, I would love it if you would support the show by:

- telling your friends.

- sharing this episode using the social sharing buttons below.

- subscribing to the show and leaving a rating and review in iTunes. Not sure how? Just follow these simple steps here or watch the short video tutorial, http://youtu.be/rq4OCyRGjHc?list=UUH3MfNZLXlKgionAs6kMT_Q

- subscribing to the show in Stitcher, http://www.stitcher.com/s?fid=54499&refid=stpr

Thanks so much for your support!

]]>If you have an event or class you would like to submit, send an email to [email protected] and I will send you the details I need for the press release.

If you have an event or class you would like to submit, send an email to [email protected] and I will send you the details I need for the press release.

]]> ]]>

]]>

Pete Braspenninx is an artist blacksmith living in Cazenovia, Michigan and is the owner of Phyre Forge. He graduated from the University of Michigan School of Art and Design in 2004 with a focus in ceramics and jewelry. Since being exposed to the blacksmith craft 14 years ago he has focused on transforming line into a continuous form with meticulous traditional joinery. He has started a body of work called “Calculating Infinity” and there are 25 pieces in this body of work. We talk about the what, why and how he calculates infinity. We also talk about his upcoming demonstration at the 40th Quad State Round up in Troy, Ohio.

Pete Braspenninx is an artist blacksmith living in Cazenovia, Michigan and is the owner of Phyre Forge. He graduated from the University of Michigan School of Art and Design in 2004 with a focus in ceramics and jewelry. Since being exposed to the blacksmith craft 14 years ago he has focused on transforming line into a continuous form with meticulous traditional joinery. He has started a body of work called “Calculating Infinity” and there are 25 pieces in this body of work. We talk about the what, why and how he calculates infinity. We also talk about his upcoming demonstration at the 40th Quad State Round up in Troy, Ohio. That leads me to today’s sponsor, a big thank you goes out to SOFA and the Quad State Round Up Conference which started in 1977, 40 years ago. The dates of the conference are September 22 to the 24th at the Miami County Fairgrounds in Troy, Ohio.